SAS Field Quality Analytics

Detect emerging issues sooner. Find root causes faster. And shave months off your issue detection to correction time.

IDC research shows that 59.8% of manufacturers stated that warranty/recall management was business critical and that the business would stop without it. Unfortunately, organizations too often regard the warranty process as part of an aftermarket activity which has limited impact or no impact on the rest of the organization."Aly Pinder, Jr. Program Director, Service Innovation & Connected Products IDC

Get to know SAS Field Quality Analytics

Key features

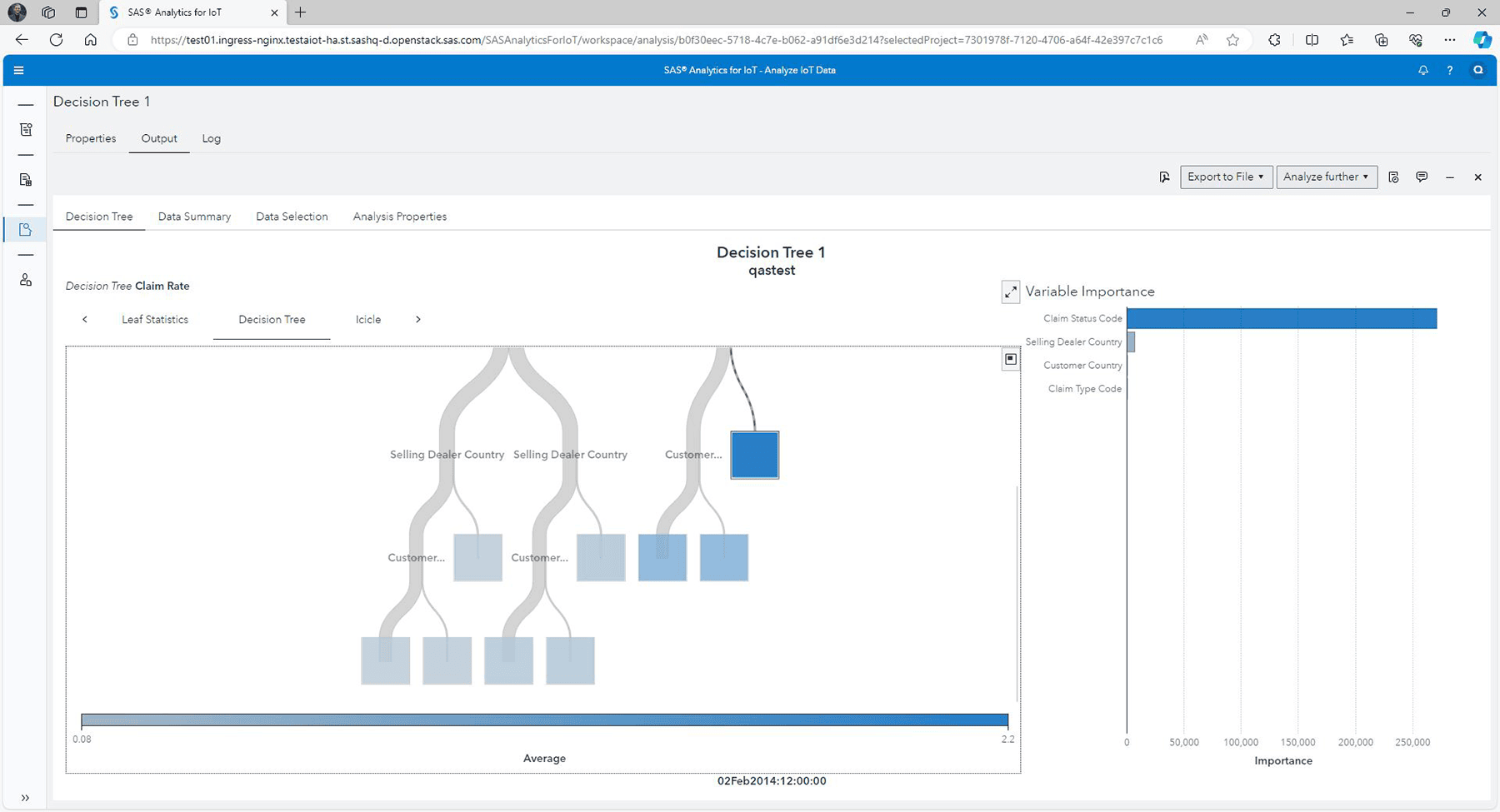

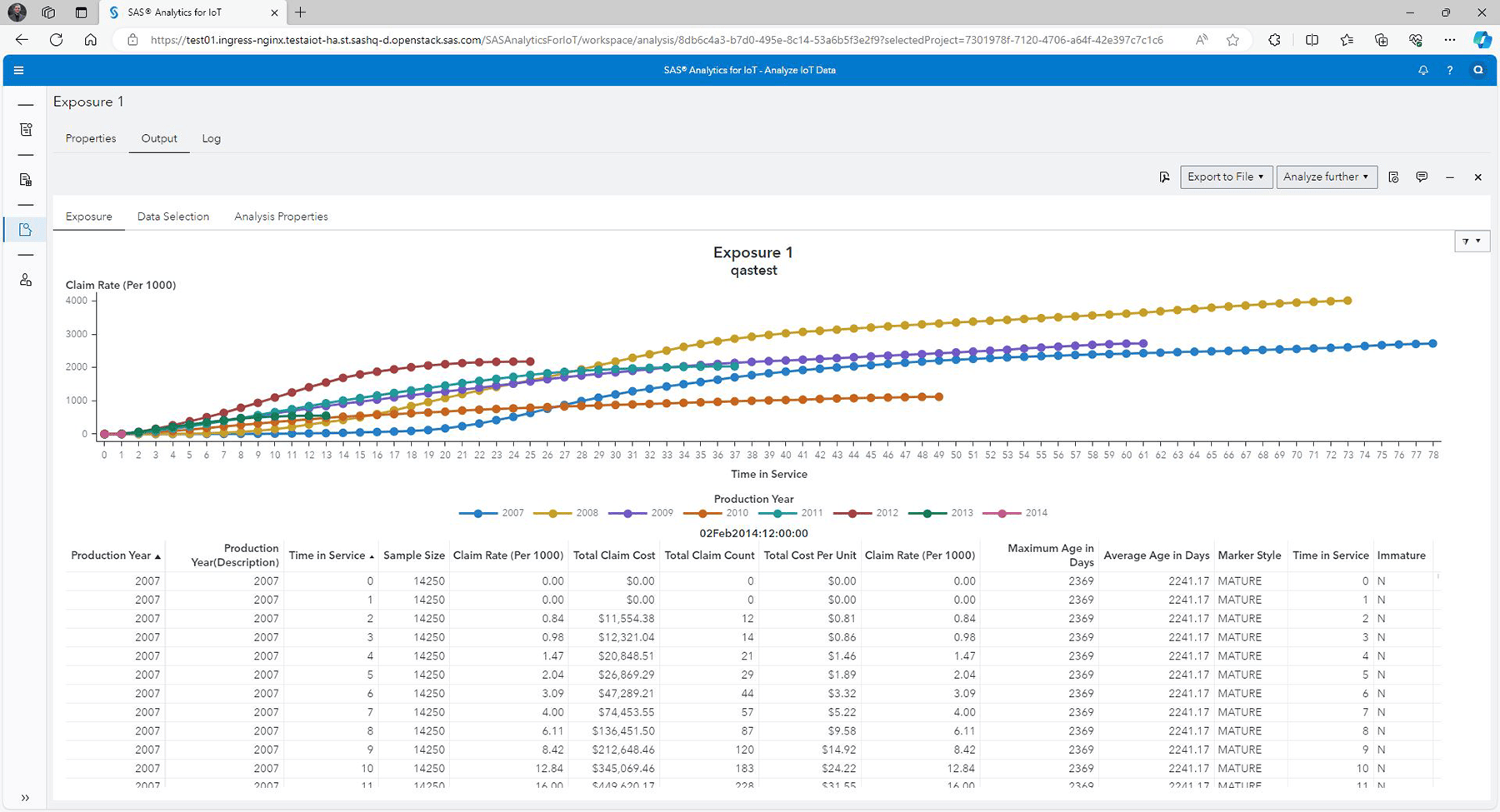

Get a comprehensive view of field quality by merging field performance data with key customer, product, manufacturing and geographic information. Then apply predictive analytics to identify issues quickly so you can address them proactively before they escalate and irreparably damage your brand reputation – and bottom line.

Data management

Lets you consolidate data from disparate sources using a standard, extensible data model. With flexible database support, you can store models in SAS or third-party databases, such as SAP HANA and Hadoop.

Prebuilt calculations

Addresses the complexities of warranty data with integrated business rules and algorithms for sales lag profiles, usage distributions, maturity calculations, seasonality adjustments, etc.

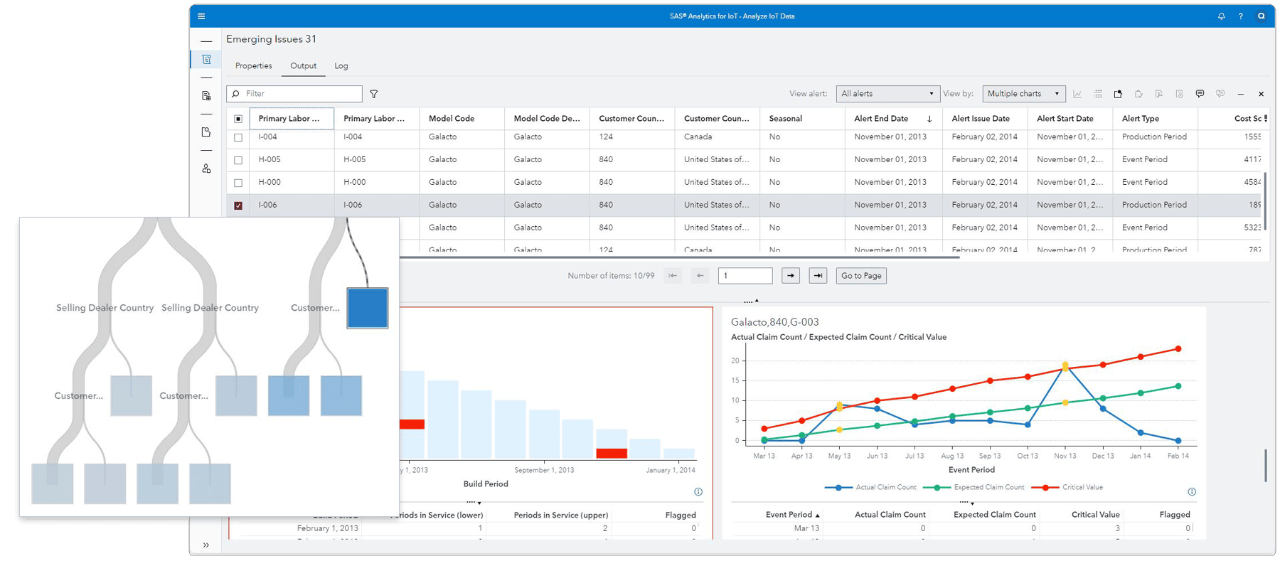

Interactive issue analysis interface

Accelerates the issue investigation process by enabling easy drill-down on one or more data points to get details on emerging issues.

Automatic anomaly detection

Monitors emerging issues by automatically detecting anomalies based on violations of analytically driven critical values or manually input thresholds.

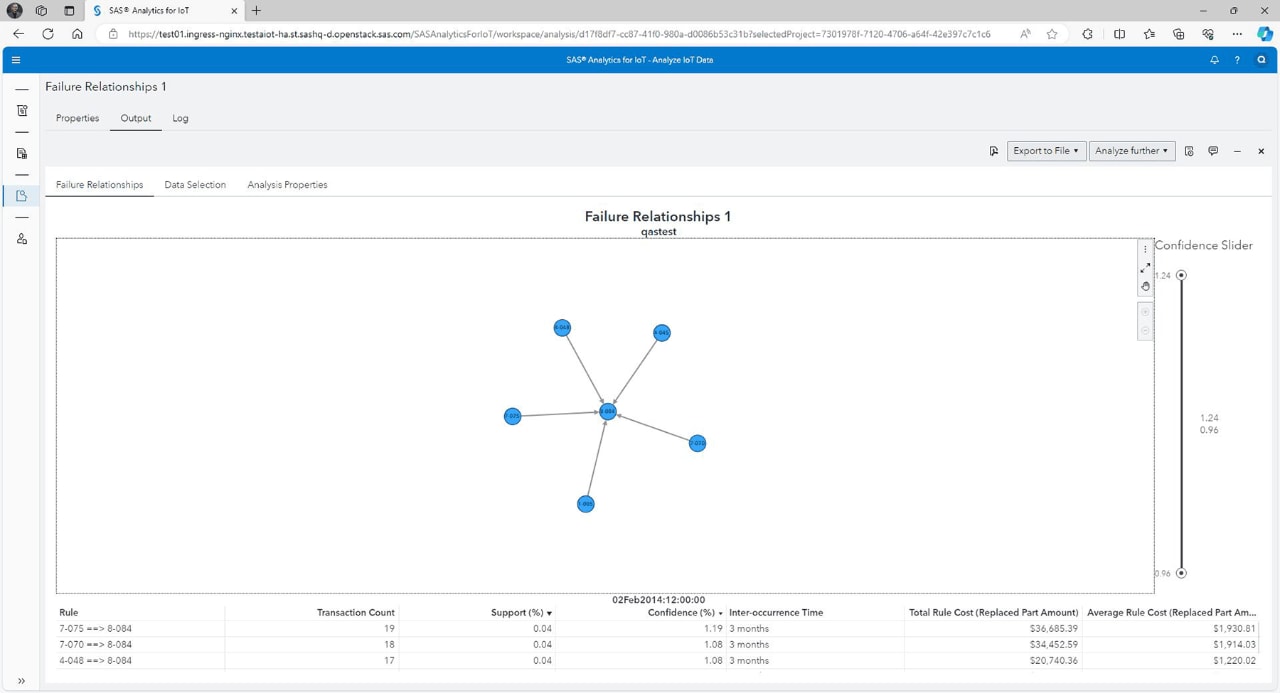

Integrated text analytics

Extracts and categorizes essential information from large volumes of unstructured data and combines it with structured data to reveal patterns and uncover related claims.

Self-service reporting

Lets you easily create reports using simple selection filters to define data sets and other criteria.

Cloud native

Compatible with cloud technologies – including Docker and Kubernetes – for large-scale, elastic, multitenant, distributed services. Ready-made to take advantage of the large volumes of data generated by the IIoT.

APIs

Call data selections and launchers to retrieve the latest data, and transform it for analysis. Call calculations to deal with unique warranty-related issues, such as sales lag, usage, maturity and extrapolation. Call analyses to refresh output and populate reports.

Organizations of all sizes are working smarter with SAS

Related products & solutions

- SAS® Asset Performance AnalyticsHarness M2M and sensor data to boost uptime, performance and productivity while lowering maintenance costs and reducing your risk of revenue loss.

- SAS® Production Quality AnalyticsGain a holistic view of quality across the enterprise and throughout the entire supply chain.